Smart PDLC Film

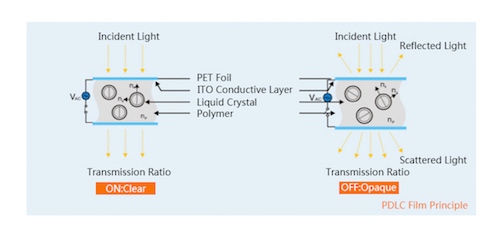

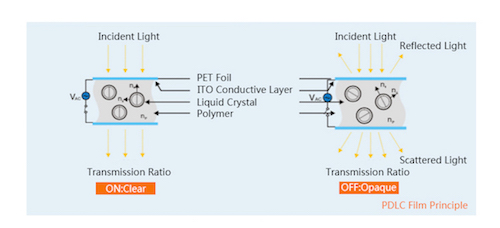

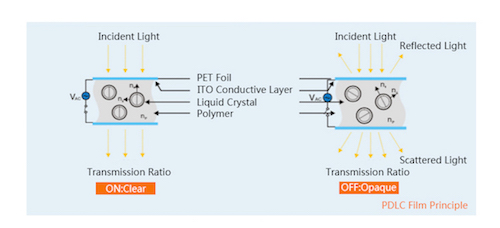

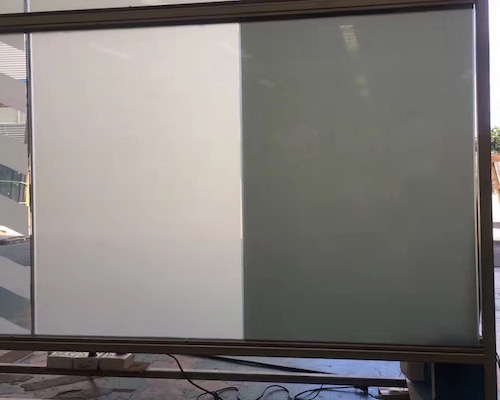

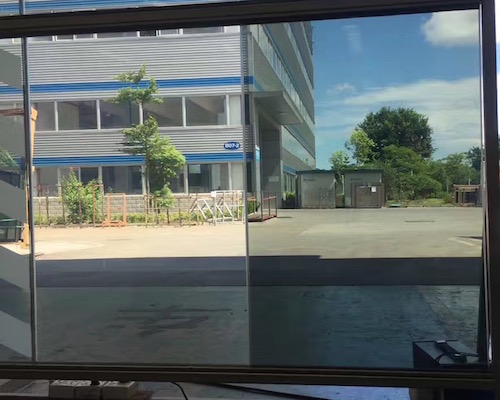

Smart PDLC film classic type non- adhesive type (polymer dispersed liquid crystal film) which is a kind of high-tech product can switch from opaque to transparent instantaneously under electricity application. It is transparent when power on and it is opaque when power off. It can be regulated and adjusted the light transmittance pass through the film by electricity supply.

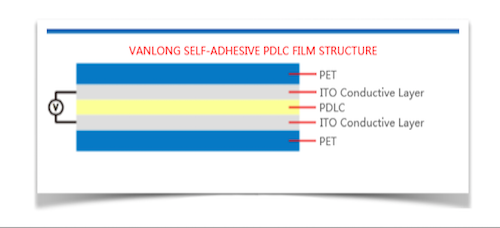

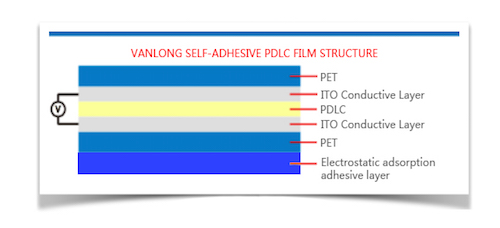

The film is composed of PET film,ITO film,polymer and liquid crystal molecules. When the film is under off state, the randomly aligned liquid crystal molecules stay along on the walls of capsule, the reflection of liquid crystal molecules and polymer makes light disperses then it is opaque. While electricity supplied, these molecules arrange themselves in a specific direction then parallel light can pass through the film makes it transparent.

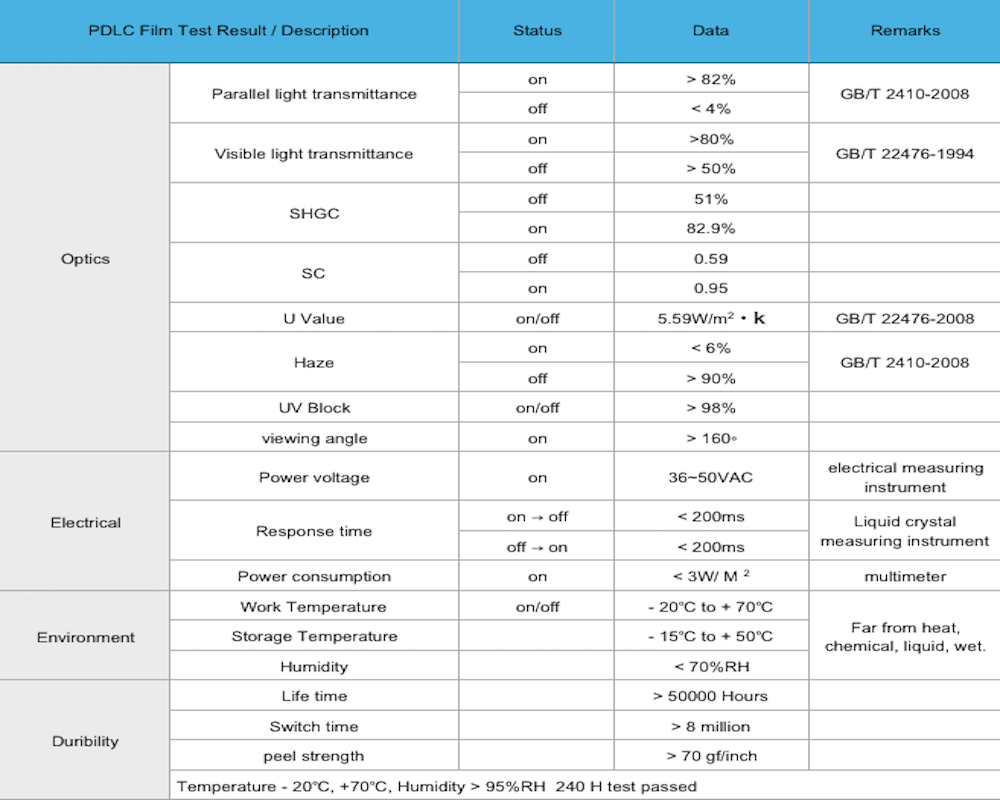

Specification of Our PDLC Film ( Classic non-adhesive PDLC Film for lamination)

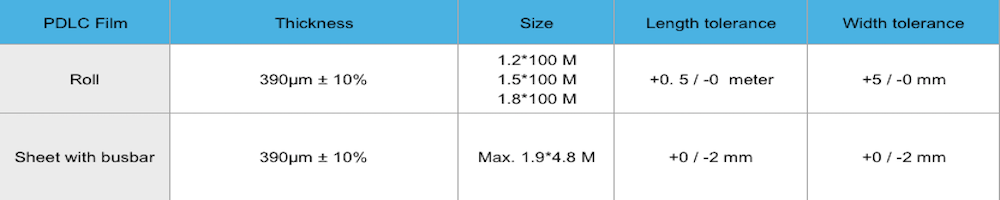

Standard size for PDLC Film ( Classic non-adhesive PDLC Film for lamination)

Self adhesive PDLC Film is identical film which provides a simple and cost effective alternative to PDLC Film technology. ItŌĆÖs with a self adhesive cling layer on one side which can be directly sticked to the existing glass surface and switch from opaque to transparent instantaneously under electricity application. It can meet the double requirements of glass on penetrability and privacy protection. This film can also be converted into a highly demanded rear projection screen with incredible image quality due to its liquid crystal properties which give high contrast features.

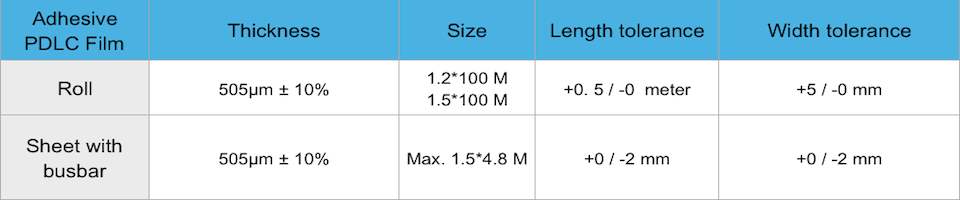

Standard size of our self adhesive PDLC Film ( dry paste directly on glass surface )

CHARACTERISIC

- Easy Transportation and Installation

Self-adhesive PDLC Film is simpler and safer transport compares to glass, can paste on existing glass surface, easy and fast install. Can Achieves the same purpose of immediately change from transparent to opaque.

- Widely Range of Applications

Self-adhesive PDLC Film use dry paste method to paste it onto the glass surface, if there is any failure or update needed, the film can be directly removed and then re-paste after glass cleaning, no need to remove the whole piece of glass.

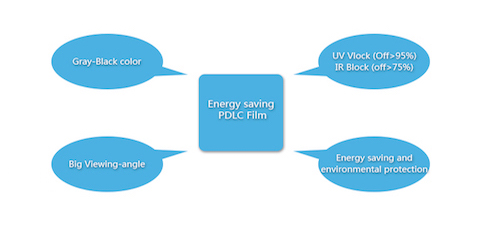

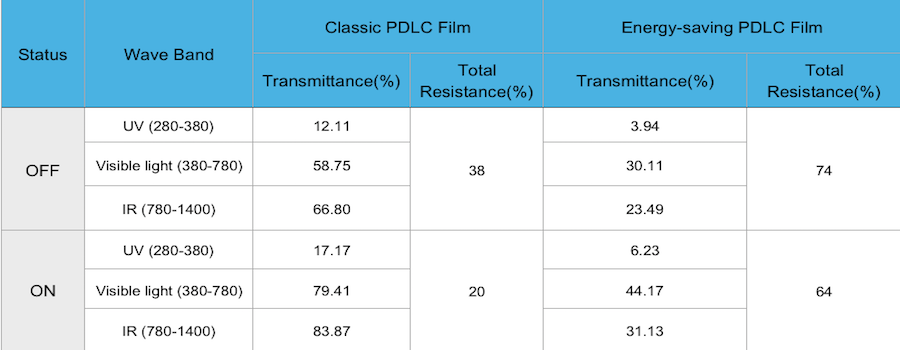

Energy-saving smart PDLC film grey color has the same clarity as typical PDLC Film, it is dark-gray color when opaque. Its not only owns excellent characteristics function of ordinary PDLC Film but also has a very good heat-insulation function, this is the building energy-saving transformation or building energy-saving design preferred.

To achieve the balance of heat-insulation and clarity through the way of reflection, conduction and absorption, while blocking the infrared, visible light and ultraviolet light.

Solar heat insulation rate = 3% UV resistance +44% Visible light resistance + 53% IR Resistance

Analysis and comparison of main parameter

Milky white color film compares to Grey color energy saving film

Competitive Advantages of VANLONG PDLC Film

High clarity and Low haze when power on, High haze to keep privacy when power off.

In roll or in customized sizes, width 1.2/1.5/1.8 meters, length over 100 meters. Can be special made 2.2 meter width for clients.

Milky white, gray and brown colors available.

Fully Covered processing production of raw material ITO and PDLC Film, guarantee on stable quality and fast lead time.

Operation temperature from cold -20Ōäā to hot +70Ōäā.

Safety low driving voltage, low power consumption.

High strength of adhesive, long life-span.

Copyright ? 2017 Shenzhen Vanlong Technology Co., LTD

All Rights Reserved. DGYIMI.com

National Hotline

Contact 0086-180-2877-5520